Alchemy Ceal – High Pressure Sealing (HPS) Range - Alchemy Oilfield Services

Alchemy HDCeal & LDCeal

High Pressure Sealing Range

Alchemy’s Ceal range of sealing products provide a flexible sealing system for a variety of scenarios.

The Ceal range of products are routinely used for P&A, pack off, to prevent annulus communication, leak path sealling, valve improvement and control line sealing and inhibition.

HDCeal and LDCeal are two part liquid systems consisting of a base liquid and catalyst liquid which when mixed will set and cure in a time dependent (rather than pressure dependent) system. The two parts are mixed at the work site prior to injection into the area where sealing is required.

Alchemy can vary the pumpable time, setting and curing times of the system by adjusting the formulation to client requirements. The product can also be produced in a variety of densities allowing it to float or sink to the application location depending on access points – the HDCeal is the higher density variant, LDCeal being the lower density formulation.

Alchemy produces several standard formulations for use in different ambient temperature regimes and viscosities. These are 100, 150 and 300. The 100 series is used in lower ambient temperature conditions, and the 300 used in higher temperatures such as in the Middle East or Africa. Our 150 product is a lower viscosity version of the 100 product which allows for easier pumping, especially when used in microbore or control lines.

Once cured, the Ceal range of products set up to form a hard solid material which holds pressure by packing off against the void or area in which it is placed. The HPS range can hold high pressure levels over long time periods, and the product life has been tested at over 30 years.

The product range is hydrophobic and will displace water on application. It is also non-conductive which makes it highly suitable for use in the offshore wind sector and as a coating to prevent corrosion. It is available in paint form as “Coat-n-Ceal”.

The Ceal range of products can be removed by using Alchemy CealSolve dissolver.

- HDCEAL®

- LDCEAL®

- COAT N CEAL®

HDCEAL®

Alchemy HDCeal® range of sealing materials (HDCeal® 100, HDCeal® 300 and HDCeal® CG) is a high density, flexible sealing system based on the application of a fluid material which sets and cures in a time dependent system. The material is deployed as a two part system which is mixed at the work site before being injected into the area in which sealing is required. The application work time and the setting and curing time may be varied by the relative proportions of chemicals (Base and Catalyst) added together and injected into the required area. The ambient temperature as well as the temperature of the application area will also be related to the pumping/working time/pot life and curing time of the product.

LDCEAL®

Alchemy LDCeal® range of sealing materials, LDCeal® 100 and LDCeal® 300, is a low density, flexible sealing and insulating system based on the application of a fluid material which sets and cures in a time dependent system. The material is deployed as a two part system which is mixed at the work site before being injected into the area in which sealing and insulation is required. The application work time and the setting and curing time may be varied by the relative proportions of chemicals (Base and Catalyst) added together and injected into the required area. The ambient temperature as well as the temperature of the application area will also be related to the pumping/working time/pot life and curing time of the product.

.

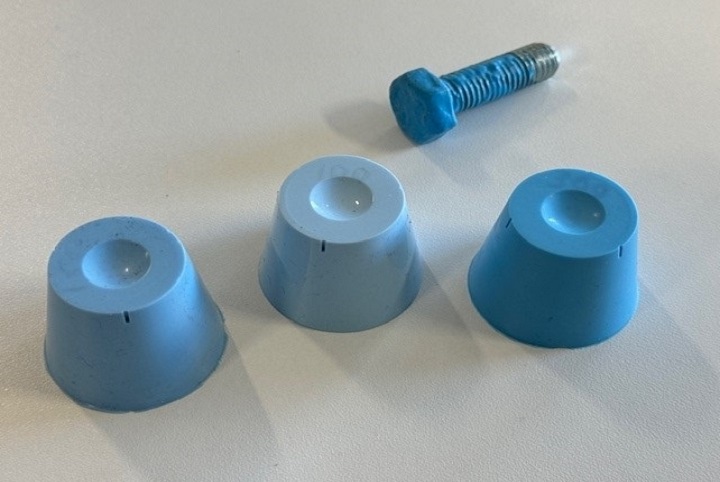

COAT N CEAL®

This peel-able paint system can be applied at various temperatures to provide a surface coating or a sealing gasket which can be removed by hand. These materials give protection to the application area but are easily removed for inspection purposes. They leave the surface cleanly and unless heavily coated require no tools for removal. The Coat-N-Ceal® product can also be used as a liquid gasket material which will solidify to provide a secure gasket system. The ease of removal after use or in reworking the area avoids the need to redress the faces of the components for reuse and the Coat-N-Ceal® can be easily removed by peeling or use of a pallet knife.